Natural draft cooling towers are engineering structures known for their energy efficiency and operational reliability in industrial facilities with heat loads around 450 MW. These towers are especially significant in sectors like power generation, petrochemicals, and large-scale manufacturing, where continuous and cost-effective cooling solutions are paramount. This blog looks at the principle, use, benefits, drawbacks, and top makers of natural draft cooling towers. It offers insights for those wanting strong solutions from Cooltech Engineers Private Limited.

What is a Natural Draft Cooling Tower?

A natural draft cooling tower is a high-capacity heat removal system that optimizes air flow without relying on mechanical fans or motors. People often see its famous hyperbolic shape at big industrial plants.

This design helps improve vertical air movement. It makes the cooling process quiet and energy efficient. Water heated by industrial equipment moves through the tower. It spreads across fill media. Cooler air from outside rises through the tower. As this happens, some of the water evaporates. This process helps carry away extra heat.

The simplicity behind this technology belies its effectiveness, by using the “chimney effect,” the tower continuously draws fresh air upward, allowing vast volumes of water to be cooled with minimal operating cost. Site planners often choose natural draft models for facilities that need constant, high-volume cooling.

Principle of Natural Draft Cooling Towers

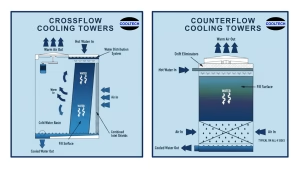

At its core, a natural draft cooling tower employs principles of convection and evaporation. Warm water returns from the industrial process and disperses over fill material, greatly increasing its exposure to ambient air. As the water flows down, cool air absorbs heat. This happens through direct contact and evaporation, which lowers the water’s temperature.

Hot, moist air rises because it is less dense. It leaves from the top of the tower. This is called the stack or chimney effect. This process runs indefinitely, powered solely by the natural differences in air temperature and density within the tower. No mechanical fans means less electrical consumption and lower maintenance requirements, keeping operational costs minimal.

Applications of Natural Draft Cooling Towers

Natural draft cooling towers are most commonly found in:

- Thermal power plants

- Nuclear power stations

- Oil refineries and petrochemical facilities

- Large manufacturing complexes

Their design and scale make them ideal for scenarios with substantial heat loads and continuous water demand. In these settings, a single tower often serves the needs of multiple high-energy processes, while regulatory compliance and reliability remain uncompromised.

Advantages of Natural Draft Cooling Towers

Natural draft cooling towers offer several compelling benefits for industrial users:

- Energy efficiency: Absence of mechanical fans leads to lower energy consumption and ongoing savings.

- Low maintenance: Fewer moving parts translate to reduced wear and minimal upkeep costs.

- High-volume cooling: Capable of handling millions of liters of water daily, perfect for large-scale applications.

- Quiet operation: The design eliminates mechanical noise, supporting quieter plant environments.

- Long service life: Robust construction ensures decades of continuous performance.

Disadvantages of Natural Draft Cooling Towers

Despite their many strengths, natural draft cooling towers do come with certain limitations:

- High initial investment: Their enormous, complex structures necessitate significant upfront capital.

- Size and aesthetics: Large footprint and conspicuous appearance may complicate site selection and local approvals.

- Limited flexibility: Not economical for small factories or sites with fluctuating cooling loads.

- Climate sensitivity: Cold environments may require special measures to prevent freezing and maintain performance.

By learning about natural draft cooling towers, industrial buyers and engineers can make smart choices for their cooling needs.

Cooltech Engineers helps customers by providing customized cooling towers. These include natural, induced, and forced draft types.A natural draft cooling tower is a powerful system for removing heat. It uses air flow and does not need fans or motors.

They also offer a wide range of durable, energy-efficient cooling tower parts. These parts include FRP fans, treated wood sections, gearboxes, and nozzles. These components help extend equipment life and improve system performance. This combination of product expertise and quality parts supply positions Cooltech as a trusted partner in delivering continuous, cost-effective industrial cooling solutions.

FAQs around Natural Draft Cooling Towers

What is the difference between mechanical draft and natural draft cooling towers?

Natural draft cooling towers work like chimneys. They use the temperature difference between the air inside and outside. This difference creates air flow. In mechanical draft cooling towers, fans create the air flow.

What is the difference between natural draft and forced draft?

A natural draft cooling tower system relies on the upward movement of heat to draw air through the heat exchanger and out via the chimney. The hotter the firebox becomes, the quicker the air ascends. Consequently, natural draft systems excel more in cooling than in heating.

How does natural draft work?

Natural draft is the airflow that moves up a chimney. It is caused by the stack effect. This effect pulls air for combustion through the burner or fuel bed.