What is a Crossflow Cooling Tower?

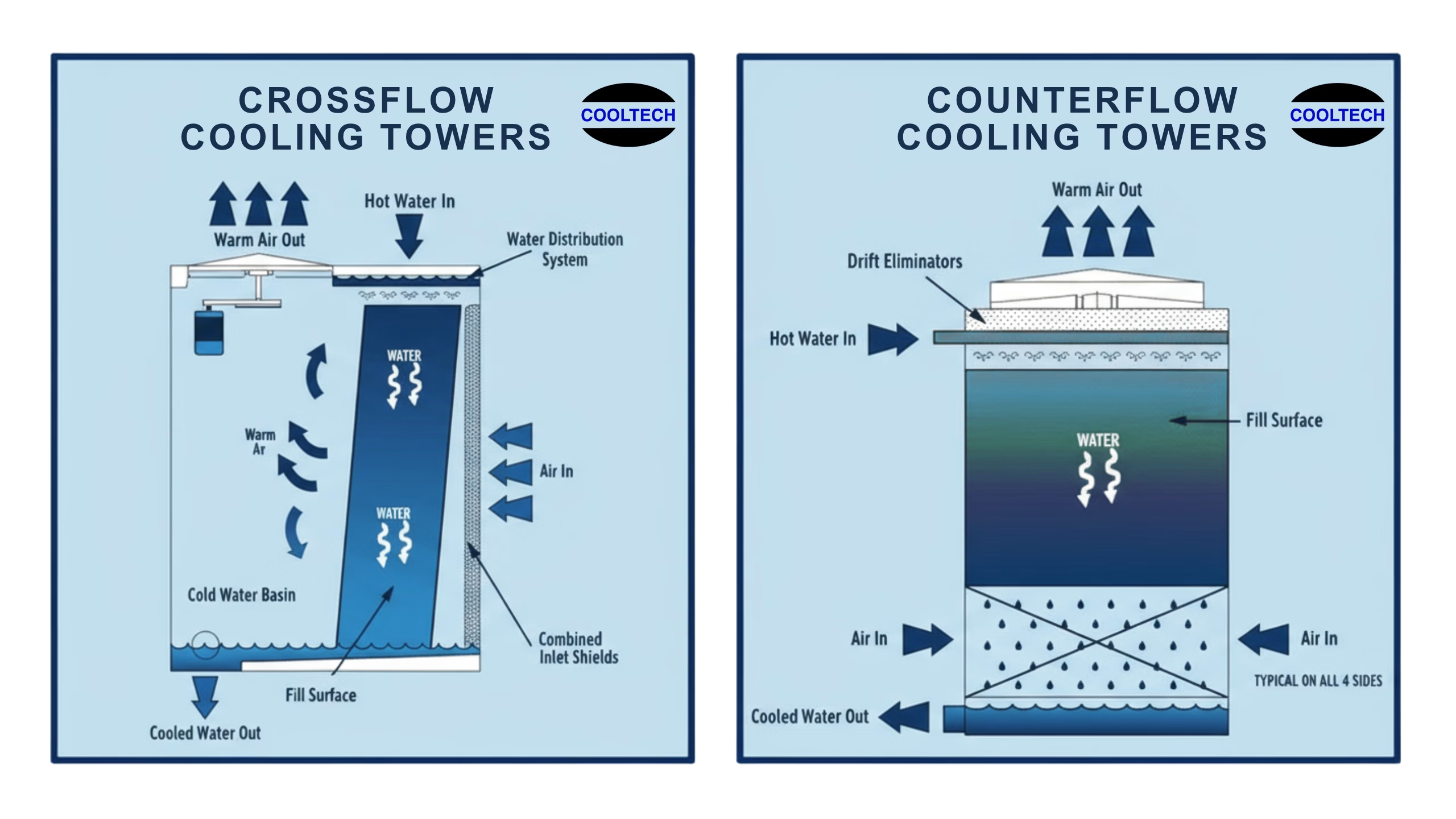

Crossflow cooling towers are specialized systems designed to reduce water temperature in industrial plants and HVAC setups. In this design, hot water spreads across the top of the tower. It flows down through fill material, making thin layers or droplets of water. At the same time, air moves horizontally through the tower crossing the falling water, either helped by fans or guided by natural airflow.

During this process, the air absorbs heat from the water through evaporation, which cools the water. The cooled water is then collected in a basin at the base and circulated back for reuse, while the warm, moist air exits through the sides. Crossflow towers are different from counterflow towers. In crossflow towers, air moves sideways across the water stream. Their simple design, easy upkeep, and dependable cooling make them a popular choice for many industrial and HVAC uses.

How Does Crossflow cooling tower work?

Crossflow cooling towers use a combination of gravity-based water distribution, horizontal airflow, and evaporation to maintain water at the right temperature.

Gravity-Based Water Distribution

Crossflow cooling towers distribute water using gravity instead of pressurized spray nozzles. The process takes place as follows:

- Warm water from industrial equipment, power plants, or HVAC systems collects in the hot water distribution basin at the top of the cooling tower.

- The water flows downward by gravity through drilled holes or weirs, ensuring even distribution over the fill media.

- Fill media such as splash pads or structured packings break the water into thin films or droplets, increasing surface area for better heat transfer.

- Greater surface area enhances the evaporation process, improving cooling efficiency.

- The gravity-based system uses less pumping power than pressurized nozzle systems, saving energy.

- However, the basin can become clogged, causing uneven water distribution.

- Regular cleaning and maintenance prevent clogging and maintain efficient performance.

Horizontal Airflow

- In crossflow cooling towers, air moves sideways across the water that flows down. This is different from counterflow towers, where air moves up against the water.

- Large fans at the top or sides draw ambient air horizontally through one side of the tower.

- As air passes across the water trickling down the fill media, it absorbs heat through evaporation, cooling the water.

- The warm, moist air is discharged through exhaust vents at the top of the tower.

- Cooled water collects in the basin at the bottom for recirculation.

- The horizontal air-to-water flow design allows easier access to the open water basin, making maintenance and servicing simpler.

- However, because the water is exposed, crossflow towers are more susceptible to freezing in cold climates.

Evaporative Cooling

- The core function of a crossflow cooling tower relies on evaporative cooling, where heat is removed from water as part of it evaporates within the moving air stream.

- Ambient air flows horizontally across the falling water, absorbing heat and causing a portion of the water to evaporate.

- This evaporation process removes heat energy, lowering the temperature of the remaining water.

- Crossflow towers efficiently handle large thermal loads while consuming relatively little energy.

- Continuous evaporation requires a steady water supply and effective water treatment systems.

- Proper control of mineral scaling and microbial growth is essential to maintain performance and extend the tower’s service life.

Recirculating the Cooled Water

- After the water passes through the fill media, it cools the air. Then, it collects in the cold water basin at the bottom of the cooling tower.

- This cooled water is then recirculated back into the HVAC or industrial system to absorb more heat, maintaining a continuous thermal exchange cycle until the desired temperature is reached.

- Drift eliminators placed at the tower’s outlet capture water droplets carried by the airflow, reducing water loss and improving efficiency.

- Blowdown systems maintain water quality by discharging a portion of the circulated water and replacing it with fresh water, preventing mineral buildup and scaling.

- This combined operation ensures consistent cooling performance, lower operational costs, and reduced downtime in crossflow cooling towers.

Advantages of Crossflow cooling tower:

- Energy Efficiency: Crossflow towers require lower fan power compared to counterflow designs, as air moves laterally across the descending water, reducing aerodynamic resistance and energy consumption.

- Reduced Pumping Energy: Their reliance on gravity-driven water distribution, rather than pressurized spray nozzles, lowers the pumping power needed, contributing to overall operational energy savings.

- Simplified Maintenance: The open and accessible hot water basin design facilitates easier inspection, cleaning, and servicing compared to the enclosed basins commonly found in counterflow towers.

- Suitability for Large-Scale Cooling: Crossflow towers are ideally suited for extensive cooling requirements in power generation plants, heavy manufacturing facilities, and large commercial HVAC systems due to their robust design and scalability.

- Low Noise: The reduced air velocity in the airflow path and efficient fan arrangement contribute to decreased operational noise, making crossflow towers suitable for installations near noise-sensitive environments such as residential areas.

______________________________________________________________________________________________________

What is a counterflow cooling tower?

Counterflow cooling towers are essential for water cooling in industrial and HVAC systems, operating on the principle of countercurrent flow. In these towers, air moves upward in the opposite direction to the downward flow of hot water, hence the name ‘counter’.

The hot water is distributed over fill media that provide an extensive surface area for effective heat transfer with the ascending air, which is propelled by fans or natural draft. Through evaporative cooling, heat is transferred from the water to the air, resulting in cooled water collecting in the basin at the bottom for recirculation. Meanwhile, warm, moisture-rich air is expelled at the tower’s top.

This countercurrent configuration improves heat exchange efficiency by maximizing the temperature gradient between the air and water. Known for their compact footprint, high thermal performance, and adaptability to various heat loads, counterflow cooling towers are widely adopted in industries for effective thermal regulation and process cooling.

How does counterflow cooling tower work?

A counterflow cooling tower operates by directing hot water vertically downward while simultaneously drawing cool air vertically upward, causing water and air to flow in opposite directions. This counter-current movement maximizes the interaction time between air and water, enhancing heat transfer efficiency through specialized fill material that expands the water’s surface area for better cooling.

The primary cooling mechanism is evaporative cooling, where a small fraction of water evaporates, absorbing heat from the remaining liquid and reducing its temperature.

The operational steps are as follows:

1. Hot water entry: Warm water is pumped to the top of the cooling tower and distributed evenly via spray nozzles.

2. Downward water flow: The water descends through the fill media, which breaks it into fine droplets or thin films, increasing surface area for improved cooling.

3. Upward air flow: Fans positioned at the bottom or top draw ambient air upward against the descending water, creating the counterflow effect.

4. Evaporative heat exchange: Contact between air and water causes partial evaporation, transferring heat from water to air.

5. Collection and recirculation: The cooled water collects in the bottom basin and is pumped back into the system for further use.

6. Air exhaust: Warm, moisture-laden air exits through the tower’s top vents.

This counterflow design optimizes thermal performance by maintaining an effective temperature gradient between air and water during their opposing flows.

Why Use a Counter Flow Cooling Tower?

This counterflow design delivers high thermal performance within a compact footprint, making it optimal for industrial cooling, HVAC systems, power generation, and process water applications where efficient heat dissipation is vital.

Advantages of Counterflow Cooling Towers:

• More compact than crossflow systems, enabling space-efficient installations.

• Generally lighter operational structures, reducing structural support requirements.

• Offers a variety of fill media options adaptable to different water qualities and application needs, enhancing versatility across diverse operational contexts.

Summarizing Crossflow vs Counterflow Cooling Tower

| Feature | Crossflow Cooling Tower | Counterflow Cooling Tower |

| Airflow Direction | Air moves horizontally across the falling water. | Air moves vertically upward opposite to the downward flow of water. |

| Water Distribution | Uses gravity-based distribution from an open top basin; no pressurized nozzles. | Uses pressurized spray nozzles for even distribution of water from the top. |

| Design Structure | Open top with side air inlets; air and water paths cross each other. | Enclosed design with air and water flowing in opposite vertical directions. |

| Heat Transfer Efficiency | Moderate; effective but slightly less efficient than counterflow due to reduced contact time. | Higher; maximized due to stronger temperature gradient and contact efficiency. |

| Energy Consumption | Lower fan and pumping power due to gravity feed and reduced air resistance. | Slightly higher due to pressurized sprays and stronger upward airflow. |

| Maintenance Accessibility | Easier to clean and inspect due to open hot water basin design. | Harder to access internal components for maintenance or cleaning. |

| Footprint | Larger size and height requirements. | More compact, suitable for space-constrained installations. |

| Noise Levels | Lower noise due to slower air velocity and efficient fan arrangement. | Slightly noisier due to higher air velocity. |

| Freezing Risk | Higher, since the open water basin is exposed to ambient air. | Lower, due to closed design that shields water flow. |

| Best Use Cases | Large-scale industrial, power plants, or commercial HVAC systems requiring easy service access. | Space-limited sites or applications demanding high heat transfer efficiency. |

Why Choose Cooltech Engineers For Your Cooling Tower Requirements?

Cooltech stands out as an industry leader through its commitment to innovation, reliability, and customer satisfaction.We have experience in making high-performance cross flow & counterflow cooling towers in FRP, RCC & Wood cooling tower systems. These towers meet and exceed industry standards. This ensures great long-term value for customers’ investments. Contact us for inquiries or any further questions.